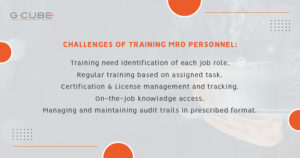

In the pharmaceutical industry, every big or small change in any policy or procedure needs to be documented. Then it needs all requisite approvals, further change management and finally training all impacted roles must take place, complete with completion tracking. Phew!

We’ve said all of it in just one sentence, but you know it does not end here. Above and beyond this are the number of people, processes and systems in admin that are required to get all this done. Therefore, there is a very high time and cost factor involved in maintaining and managing standard operating procedures (SOPs).

In our experience, there can be a significant reduction in this time and cost by embracing automation in training for SOP changes. There are four primary areas how this is achieved:

- Consolidate Information from Different Departments

- Stop Creating Change Training Manually

- Reduce Time Around TNA and Batch Creation

- No More Manual Tracking and Reporting

Consolidating of departmental information – Combining the names, roles, and job descriptions from HR systems, with the list of SOPs required for doing their job, and their individual training records, sets the foundation for future cost reduction. If the LMS can have access to these three areas of data, then it is possible to automate the view of who all are impacted by any change. Using a system driven approach versus MS Excel jugglery makes the entire process more accurate and robust.

Reduction in manual training creation – Every time an SOP undergoes change, the people impacted by this change need to know about it and understand it. This requires manual tracking and training interventions. By using the automation capabilities of an LMS, the training around changes can be created by the subject matter expert at the time of making the change in the SOP. Added to the consolidated departmental information, the LMS can identify all roles affected by every SOP change.

Reduction in TNA and batch creation time – Once the LMS knows the roles impacted by the change, it can clearly identify who needs training around the change and who doesn’t. If there is no manual training intervention then there is no need for creating batches of trainees, ensuring their availability and tracking attendance. The LMS can simply auto assign the SOP change training to the relevant roles and assign completion due dates. As everyone becomes responsible for ensuring that they complete the trainings assigned to them, there is a sense of ownership that come in.

Reduction in manual tracking and reporting time – Manual tracking of completion status requires people and time. The right LMS can provide dashboards with a broad view of tasks around any and all SOP changes. From the number of people impacted to roll out of training and all the way to completion percentage. The LMS is also able to send reminders and alerts to supervisors and managers for non-completion. Having a reporting dashboard that is automated reduces the time and resources required for creating manual reports.

Poor communication of change is said to be one of the reasons why change management processes fail. In Pharma, failure of the change management processes around documentation and training could lead to errors that impact business, reputation and compliance. While evaluating an LMS, do remember to check for its capability in managing documentation changes and whether it can help reduce administrative time and cost around standard operating procedure change training.

We at GCube, have 20 years of experience and 80+ industry awards in learning technologies; and would love to hear your thoughts, queries and suggestions. Please do write to us.